Library Magazine Articles ISO 50001 helps manage energy costs in mining

ISO 50001 helps manage energy costs in mining

Klas Bockasten - Feb 2012

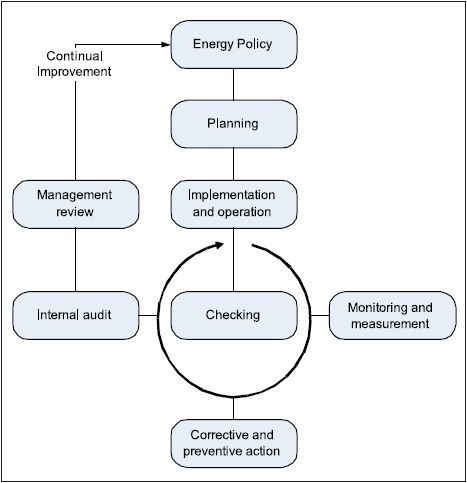

Courtesy of CAN/CSA-ISO 50001:11, National Standard of Canada

A new energy management standard – ISO 50001 – is set to provide the mining industry with technical and management strategies to increase energy efficiency, reduce operating costs and improve environmental performance. Issued in June 2011, this international standard is a voluntary measure that, according to the U.S. Energy Information Administration, could influence up to 60 per cent of the world’s energy demand.

The danger of not adopting an energy management approach comes from increased obsolescence, rising utility costs, as well as increased investor and public scrutiny on energy performance. Adopting progressive energy management systems creates opportunities to take advantage of a growing market for efficient mining modifications and the introduction of new technologies to establish sustainability leadership and brand.

Energy management model highlighted in ISO 50001

A new approach to energy efficiency

Programs and financial incentives with various government, electrical and gas utilities that encourage energy efficiency are common in many jurisdictions throughout Canada. Traditionally, energy efficiency programs have been focused primarily on identifying “low-hanging fruit,” however, and lack methods for tracking the energy savings that are achieved, thus creating a lost opportunity for communicating long- term benefits to corporate management. The lack of measurement and verification of savings from projects that have been implemented, as well as the lack of formalized processes, can result in the loss of energy efficiency improvements, for example, when individuals leave an organization and take the knowledge and practices with them.

ISO 50001 uses the same “Plan-Do-Check-Act” method - ology that succeeded for decades in driving quality improvements through ISO 9001. More recently, environmental performance has been improved in many organizations through ISO 14001. The Energy Management Systems’ voluntary international standard can help transform businesses of all types and sizes to highly efficient energy users through continuous improvement, leading to reducing energy use, costs and related emissions.

The key steps to implementing ISO 50001 include:

- Top management demonstrating its commitment by issuing an energy

- The individual facility or mine using the policy to develop an energy plan, which includes a review of current energy use and consumption, to develop an energy baseline. The plan also should identify energy savings targets with a list of energy management action

- The mine using the action plan from the planning process for implementation and operation and internally communicating and documenting its energy performance. The organization should identify and modify the operations and maintenance activities in the plan that are related to its significant energy uses, to generate energy

- The mine ensuring that energy performance is monitored, measured and analyzed at planned intervals, by checking and making corrections to address non-conformities so that the plan will stay up to

- At planned intervals, a management review should be carried out to ensure the energy plan’s continuing suitability, adequacy and

Financial drivers to implement energy management systems

The federal and provincial governments, as well several electrical utilities in Canada, have been encouraging industry to adopt the ISO 50001 standard to support a long-term energy conservation culture. The Northern Industrial Electricity Rebate program was launched in Ontario to provided a two cent per kWh rebate on all electricity consumed (about a 25 per cent rebate) for three years, provided that an energy management system was established. ISO 50001 was the basis for the energy management plan.

Improved management information systems through energy monitoring and enhanced metering of electricity and other fuels have often been incorporated into modifications in parallel with implementation of the standard.

In February 2011, a similar approach was announced by BC Hydro and BC Mining Research Ltd., an “all fuels” baseline energy audit. This program is intended to measure energy consumption by each aspect of the mine’s operations. By breaking down the operation into a detailed analysis, areas for improvement can be pinpointed and responded to. When historic costs are compared to costs in the current and future year, progress can be tracked as a way to demonstrate good stewardship and cost management.

Author

Klas Bockasten is an energy management services leader with Golder Associates. He has managed several industrial projects from initial study, detailed design and construction to commissioning of energy projects in the mining and manufacturing sectors.

.png)